Beating the Heat: Nano Coat’s Energy-Saving Solution

- By Gerry Urbina

- Oct 12, 2025

- 4 min read

Updated: Oct 13, 2025

When a shifting market began to squeeze the family lumber business, Edmund Lee did not cling to the old playbook.

He listened to demand, hunted for better solutions, and built a company around them.

Today, as founder of Trendway Builders, Inc., the official distributor of Nano Coat Anti-Heat Solution in the Philippines, Lee is proving that Filipino entrepreneurs can win by educating the market and delivering measurable results.

From Shop Floor to Solutions Partner

Lee entered the family enterprise right after graduation. Early exposure to weekend store runs and daily operations shaped his instincts for product, service, and execution.

“It’s like on-the-job training since we were young,” he recalled.

As the lumber trade slowed with the rise of PVC and other substitutes, he pivoted. Importation followed, then value-added services such as installation and warranties.

The shift was not just about introducing a new product. It was about redefining what kind of company Trendway would become.

“We are not just contractors,” he said. “We are solution providers. We assess your space and recommend what solves your problem permanently.”

The Nano Coat Proposition

Launched locally in 2010, Nano Coat is a colorless, odorless coating for glass windows and skylights. It blocks heat and UV while letting daylight through, lowering indoor temperatures and reducing air-conditioning load.

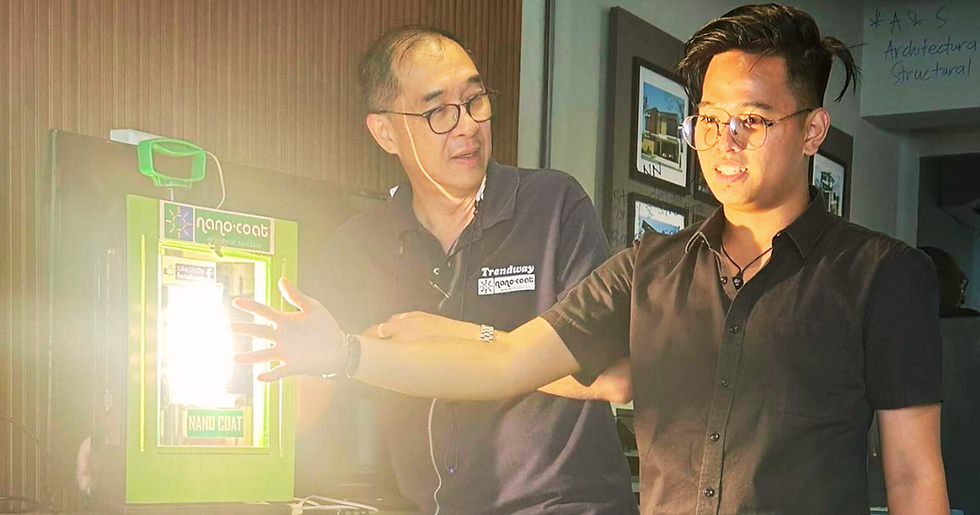

Lee demonstrates its impact through an experiential setup using a heat lamp and side-by-side glass samples. In seconds, customers feel the difference.

One result stands out. A large car showroom that previously ran six air-conditioning units at once reported that, after installation, it could operate only three or four. “You know you are saving even without doing the math,” Lee said.

Price matters too. Compared with common window tints, Nano Coat comes in about 30 to 40 percent lower on cost, and it is designed to be long-lasting and environmentally friendly.

Safety and Trust, Proven at Home

Early on, Lee knew that selling a new technology required more than supplier brochures.

He commissioned local safety testing inside Ateneo de Manila University's Philippine Institute of Pure and Applied Chemistry (PIPAC). The results showed zero traces of heavy metals such as lead, mercury, cadmium, and chromium.

“I did not just rely on overseas tests,” he said. “I had to prove to Filipinos that it is safe.”

That credibility made it easier to approach professionals and institutions. Nano Coat now serves a mix of residential, commercial, and educational clients.

For smaller projects, the team applies a mobilization fee, but the company’s service model is consistent. It includes ocular inspections, site assessments, written proposals, and in-house application done by trained installers.

Nano Coat’s minimum daily capacity is around 500 square feet, which keeps projects efficient and quality tightly controlled.

Teaching the Market to Buy

Lee spends time where many sellers do not. He gives talks in architecture schools and professional events to explain how nanotechnology works and where it is best applied.

“I wanted them to know about the technology, not just make a sale,” he said. The approach is slow but durable. Educate future decision makers today. Earn organic demand tomorrow.

During one campus forum, a student asked about the product’s downside. Lee’s candid reply captured the reality faced by many innovators: “The only negative before was that it was new.” Awareness takes time. Results build it.

A Standout Endorsement

Among Nano Coat’s many installations, one project became a milestone. The Italian Ambassador’s residence faced severe heat through its skylight. After Nano Coat’s application, the embassy shared a formal testimonial on official letterhead.

“The ambassador is so happy you solved his problem,” Lee recounted.

That letter became proof that the technology performs under exacting standards and opened doors to more institutional clients.

Beyond Glass: A Full Heat-Control System

Glass is not the only heat path. Metal roofs and concrete walls absorb and release heat into living spaces. To complete the equation, Lee added Nano Cool Reflective Coating for exteriors, which can cut surface temperatures by 10 to 15 degrees Celsius based on the company’s tests.

In one client site, an infrared reading dropped from 59°C on untreated roofing to 32°C after coating, taken at the same time of day. Using Nano Coat on glass and Nano Cool on roofs and walls creates a complete, practical package for total heat mitigation.

The Mindset Behind the Build

Lee discovered Nano Coat while taking his master’s degree in 2008–2009. He evaluated the idea with logic, data, and patience. Market need, product fit, safety validation, and a service model that would protect the customer experience.

“At the start it is always difficult,” he said.

“But if you really believe in what you are doing, good things will happen eventually. Just hang on.”

Fifteen years later, Nano Coat is no longer a niche product. It is a proven energy-saving solution that serves homes, institutions, and embassies alike — powered by a founder who chose to listen, adapt, and lead through education.

For a new generation of founders, the lesson is clear. Do the hard validation locally. Show the savings in real life. Price fairly. Teach your market. The results are guaranteed to shine through.

--

ABOUT AUTHOR

![TFD [LOGO] (10).png](https://static.wixstatic.com/media/bea252_c1775b2fb69c4411abe5f0d27e15b130~mv2.png/v1/crop/x_150,y_143,w_1221,h_1193/fill/w_179,h_176,al_c,q_85,usm_0.66_1.00_0.01,enc_avif,quality_auto/TFD%20%5BLOGO%5D%20(10).png)